Integrated Computational Materials Engineering (ICME)

A channel die compression simulation on Mg AM30

Abstract

Deformation of polycrystalline aggregates of HCP crystals was investigated

by employing crystal plasticity and finite element simulations. Results were

validated using channel die compression tests. The three dimensional

polycrystal, represented by Voronoi techniques, was assigned an initial

distribution of crystallographic orientations determined from X-Ray

Diffraction. The mechanical properties from the channel die compression tests

were used to correlate the material parameters of the crystal plasticity model.

Simulations predicted grain-to-grain interactions and the resulting texture

evolution under channel die compression. The inhomogeneous deformation among

grains was mapped by a stress and a strain distribution and grain orientation

spread. The simulation results were compared with experimental observations of

an HCP polycrystal subjected to channel die compression.

Author(s): Q. Ma, E.B. Marin, A. Antonyraj, Y. Hammi, H. El Kadiri, P.T. Wang

and M.F. Horstemeyer

Methodology

Magnesium has a hexagonal close-packed (HCP) structure whose deformation

modes are different from those of aluminum. Typical deformation modes in

magnesium are basal <a>-{0002}<11-20> slip, prismatic <a>-{10-10}<11-20&gr; slip,

second pyramidal <c+a>-{11-22}<11-23> slip and extension twinning

{10-12}<10-11>. In this study, a commercial extruded AM30 alloy (mass %, 2.54%

Al, 0.40% Mn, Mg in balance) was selected as the HCP experimental material to

conduct channel die compression at high temperature 200C and at strain rate of

0.001/S to strain 30%. At these loading conditions, twinning would not be

profuse and, hence, only slip will be the predominant deformation mode. The

hardening parameters of the three slips modes were obtained using material

point simulations to fit the experimental stress-strain curve recorded from the

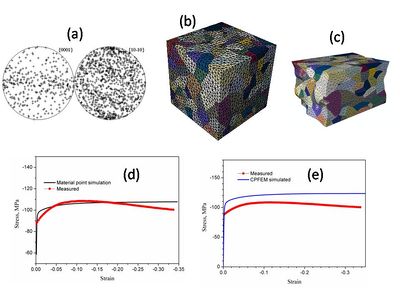

channel die compression test as shown in Figure 1d.

The texture of AM30 was measured by X-ray diffraction method (XRD). The

recalculated pole figures were calculated based on the orientation distribution

functions (ODFs) which was obtained using the measured six incomplete pole

figures {10-10}, {0002}, {10-11},{10-12}, {11-20} and {10-13}. The initial and

the channel die compressed texture of AM30 plotted by the texture software MTEX

[1].

The commercial finite element software ABAQUS 6.9 and a user subroutine UMAT

incorporating the crystal plasticity constitutive theory and the magnesium AM30

materials parameters were used to simulate texture evolution and mechanical

response. The initial texture used in this CPFEM simulation was measured in the

undeformed sample and was represented by 343 discrete orientations as shown in

Figure 1a. The 3D polycrystal is represented by the 3D Voronoi grains created

by the code Neper [2]. The undeformed polycrystal and the channel die

compressed 3D polycrystal up to a strain of 30% are presented in Figures 1b and

1c.The simulated and measured channel die compression stress-strain curves are

presented in Figure 1e.

Figure 1. (a)Initial texture; (b) undeformation 3D Voronoi structure; (c)channel die compressed 3D Voronoi grains; (d) materials point simulated and measured stress-strain curves and (e) crystal plasticity and 3D structure predicted and measurd stress-strain curves.

Material Model

VPSC: ViscoPlastic Self-Consistent

Input Data

See VPSC Input Deck for a channel die compression simulation on Mg AM30

Results

Plane strain compression simulations of a three dimensional microstructure of HCP magnesium AM30 were performed using an elastic-plastic crystal plasticity model and the finite element method. The mechanical response, global texture evolution and the intergranular heterogeneous plasticity of discrete grain were captured by the 3D Voronoi microstructure channel die compression simulation. Simulation results showed that the effect of grain interaction could play an important role on global texture evolution, the orientation spread and the local heterogeneity deformation of one grain.

Acknowledgments

The authors are grateful to the financial support from the Department of Energy, Contract No. DE-FC-26-06NT42755, and the Center for Advanced Vehicular Systems (CAVS) at Mississippi State University.

References

Antonyraj, A., Marin, E., Ma, Q., Wang, P., Horstemeyer, M., & King, R. (Oct

2010). Re-Crystallization Studies of a Channel-Die Compressed AM30 Magnesium

Alloy. TMS 2011, California.

Ma, Q., Marin, E., Antonyraj, A., Hammi, Y., Wang, P., & Horstemeyer, M. (Oct

2010). On Predicting the Channel Die Compression Behavior of HCP Magnesium AM30

Using Crystal Plasticity FEM. Magnesium Technology 2011, 583-587. Proceddings

of 2011 TMS Annual Meeting and Exhibition, San Diego, California, USA.