Integrated Computational Materials Engineering (ICME)

Visco-Plastic Self-Consistent (VPSC) Deformation Simulation of Polycrystalline FCC Aluminum

Abstract

Uniaxial compression, uniaxial tension and simple shear of

polycrystalline aggregates of Aluminum were investigated by employing the

Visco-plastic self-consistent polycrystal (VPSC) model. The starting texture is

a series crystals represented by five hundred random orientations. The deformed

texture, true stress-true plastic strain curves, average of the all grains

rotation angle along strain, Alpha and Kappa hardening curves of the aluminum

aggregates are calculated based on the VPSC model. Comparison with hexagonal

close-packed (HCP) materials, FCC polycrystalline aluminum exhibits a not

marked anisotropic yield surface property which caused by the equivalent 12

{111}<011> slips and no twinning. However, deformation texture characteristics

and average rotation angle along strain show a stable orientations tendency of

aluminum with increasing plastic strain.

Author(s): Q. Ma, A.L. Oppedal and M.F. Horstemeyer

Methodology

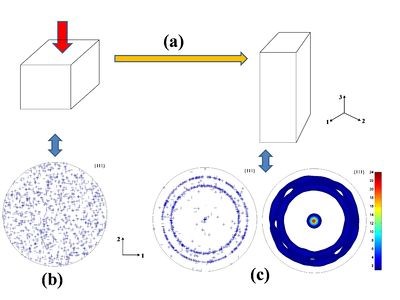

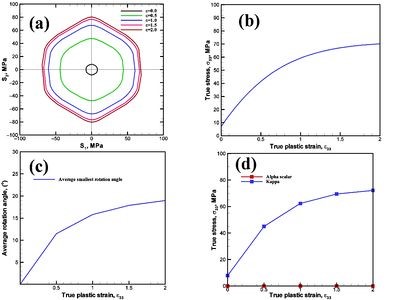

Deformation of Aluminum aggregates was simulated by the VPSC model and the twelve {111}<011> slips at room temperature. The single crystal parameters were listed in FCC.SX file which is same in compression, tension and simple shear. The only difference among the three deformations is the boundary condition. Figure 1(a) shows the uniaxial tension. A starting texture represented by 500 random orientations was shown in Figure 1(b). Figure 1(c) presents the deformed texture at strain of 2.0. Figure 2 presents the predicted yield surfaces, the true stress-true plastic strain curve, the average grain rotation angle and the Alpha and Kappa hardening curves of polycrystalline Aluminum during uniaxial tension.

Figure 1. Uniaxial tension simulation of polycrystal Aluminum based on VPSC. (a)Uniaxial tension; (b) Initial texture; (c) Deformed texture at strain 2.0. (click on the image to enlarge)

Figure 2. Predicted yield surface, stress-strain curve, average rotation angle curve and Alpha Kappa curves of Aluminum aggregates during tension. (a)Yield surface; (b) True stress-true plastic strain curve; (c) Average rotation angle; (d) Alpha and Kappa hardening curves

Material Model

VPSC: ViscoPlastic Self-Consistent

Detailed simulation results of uniaxial compression, tension and simple shear of ploycrystal Aluminum

Uniaxial

compression, tension and simple shear simulation results of polycrystalline

Aluminum based on VPSC model

A stand-alone TP tool is available from the online code repository. Please refer to the documentation (online help and tutorial) to learn how to use this tool.

Input Data

See VPSC Input Deck for Deformation Simulation of Polycrystalline FCC Aluminum

Results

Typical processings, uniaxial compression, tension and simple shear, of polycrystal Aluminum were simulated based on the VPSC model. The deformation texture, the yield surfaces at various strain levels can be directly captured by the VPSC model. The average all grains smallest rotation angles along strain and the Alpha and Kappa hardening curves can be calculated based on the output data of VPSC. All these parameter mentioned above are necessary to investigate the plasticity of metals. VPSC can also capture both the crystal scale parameters (single crystal hardening parameters) and macroscale property of the polycrystalline aggregates during deformation.

Acknowledgments

The authors are grateful to the financial support from the Department of Energy, Contract No. DE-FC-26-06NT42755, and the Center for Advanced Vehicular Systems (CAVS) at Mississippi State University.