Halo Project

Displaying the breadth of automotive engineering at Mississippi State University

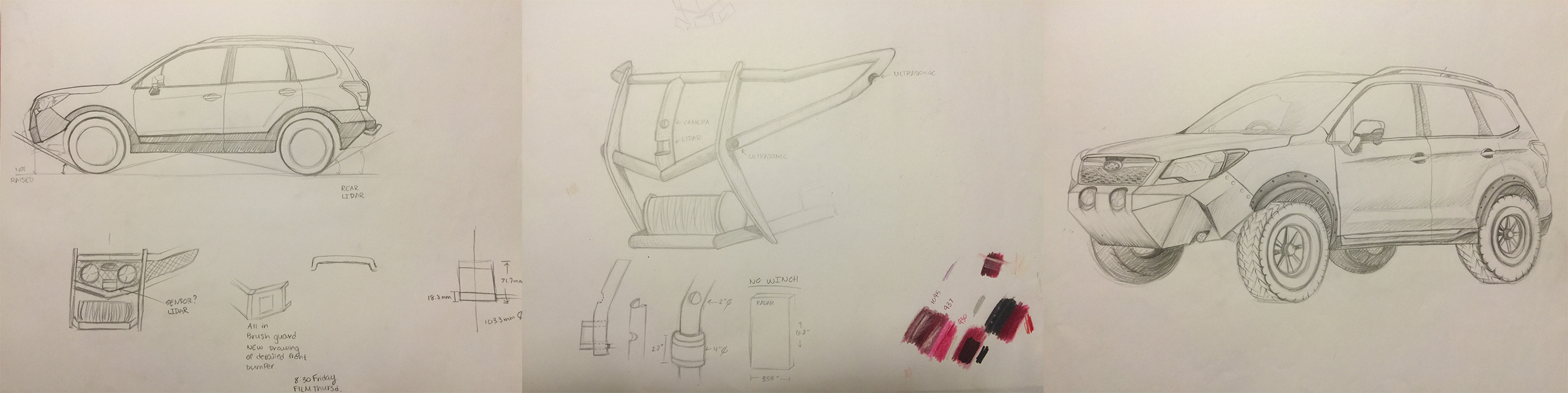

The term "halo car" often applied to an automaker's top-of-the-line vehicle which demonstrates the newest technology and represents the direction that a brand is going. Similarly, MSU's Halo Project unites MSU experts on automotive engineering to collaborate on a technological showpiece. The MSU Halo Vehicle is an off-road, all-electric SUV with advanced autonomous driving features. The project utilizes CAVS materials science, advanced powertrains, computational fluid dynamics, vehicle integration, and autonomous systems expertise.

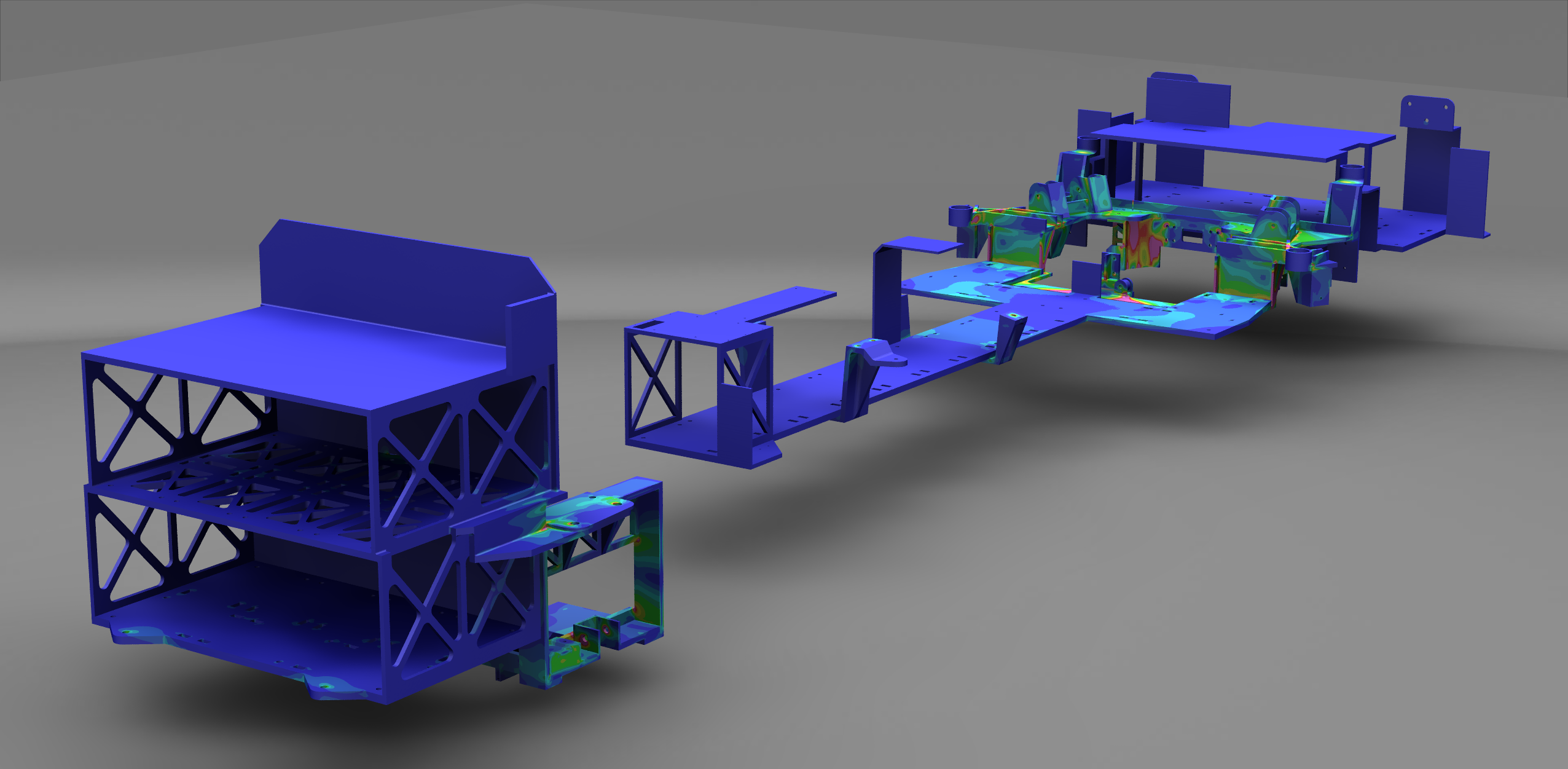

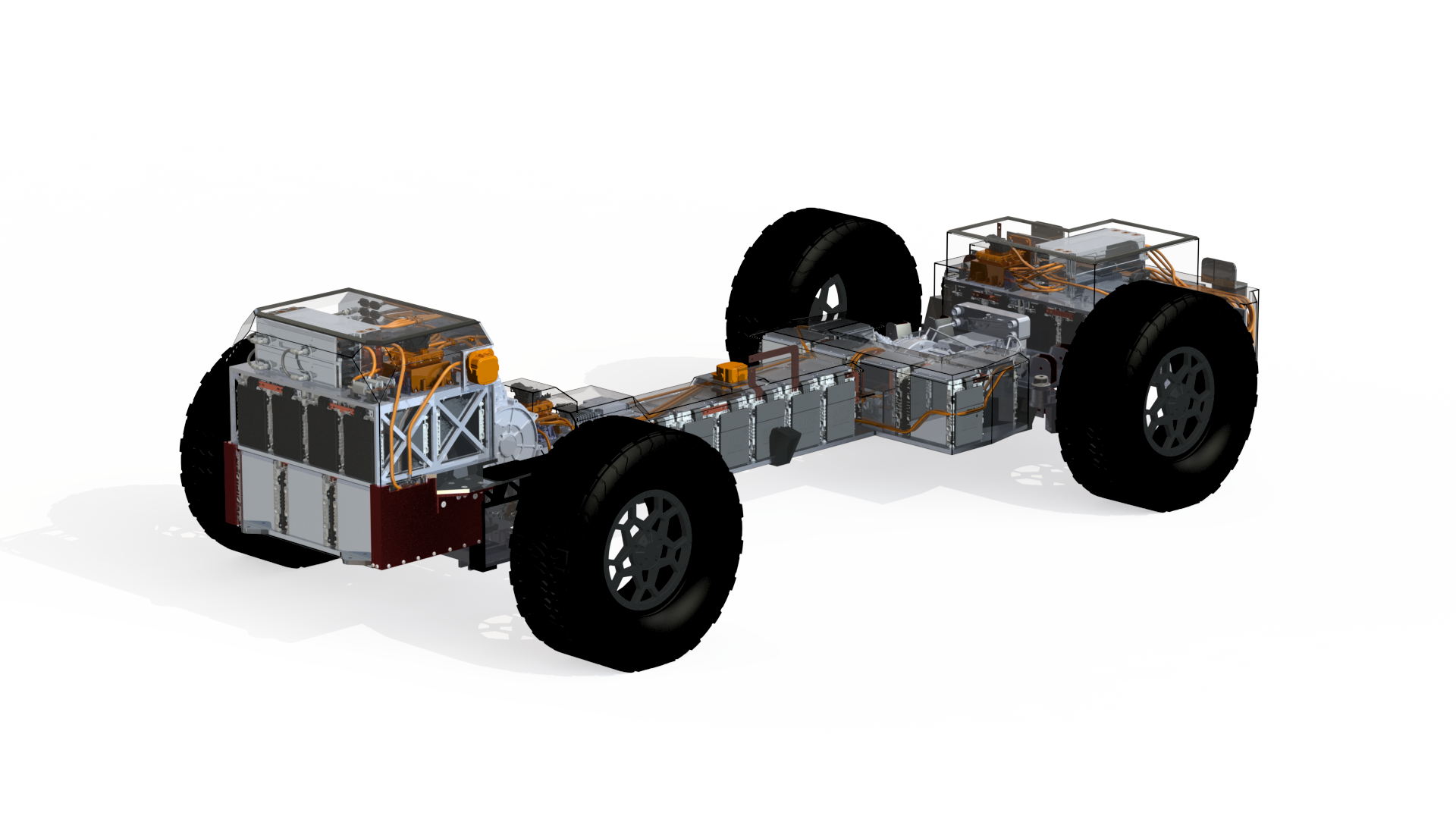

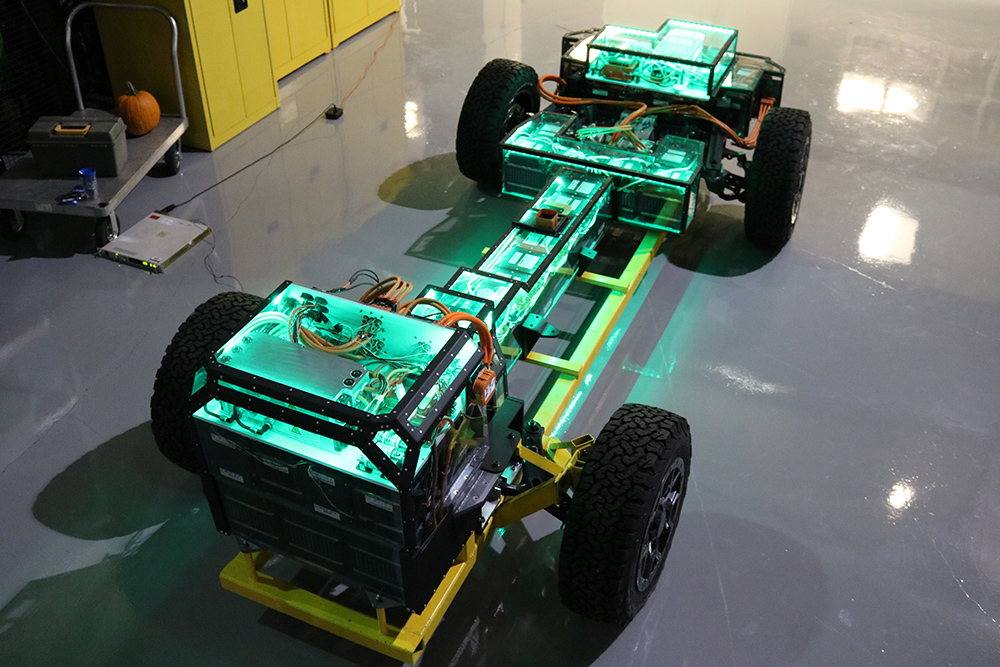

The vehicle's innovative PowerDriveLine is custom designed from the ground up to combine the functions of the traditional powertrain, driveline, chassis and suspension subsystems. By designing these systems as a single unit, the complete assembly can be optimized, which reduces both mass and complexity.

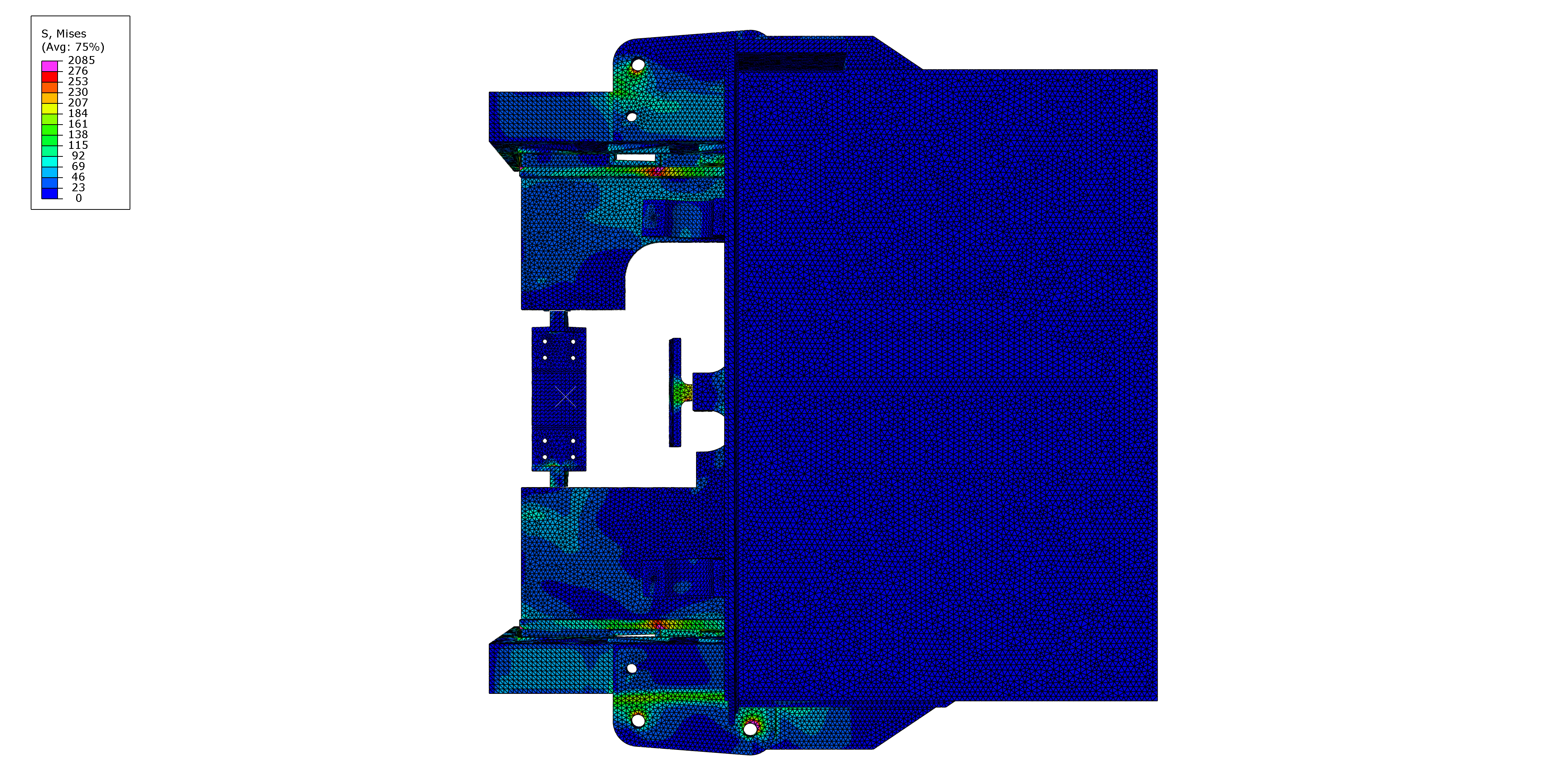

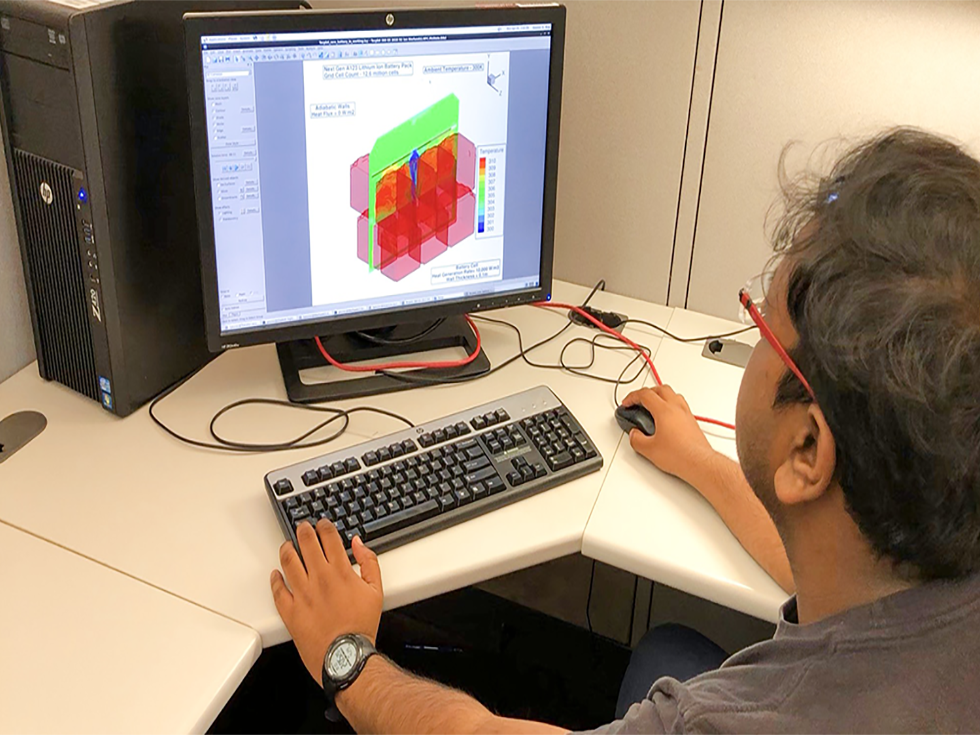

Optimizing multiple subsystems simultaneously requires extreme computational power, such as that available to CAVS experts through the High Performance Computing Collaboratory. The Halo PowerDriveLine was simulated using a model of over 5 million elements, demonstrating a new paradigm of design optimization as one of the most complex FEA models ever developed by CAVS and simulated at HPCC. It combines materials such as aluminum, titanium, and high-strength steel.

A close-up view of the vehicle's materials design and optimization properties

"This vehicle makes an impactful statement about our contribution to the future of autonomy and off-road mobility."

- Clay Walden

CAVS Executive Director

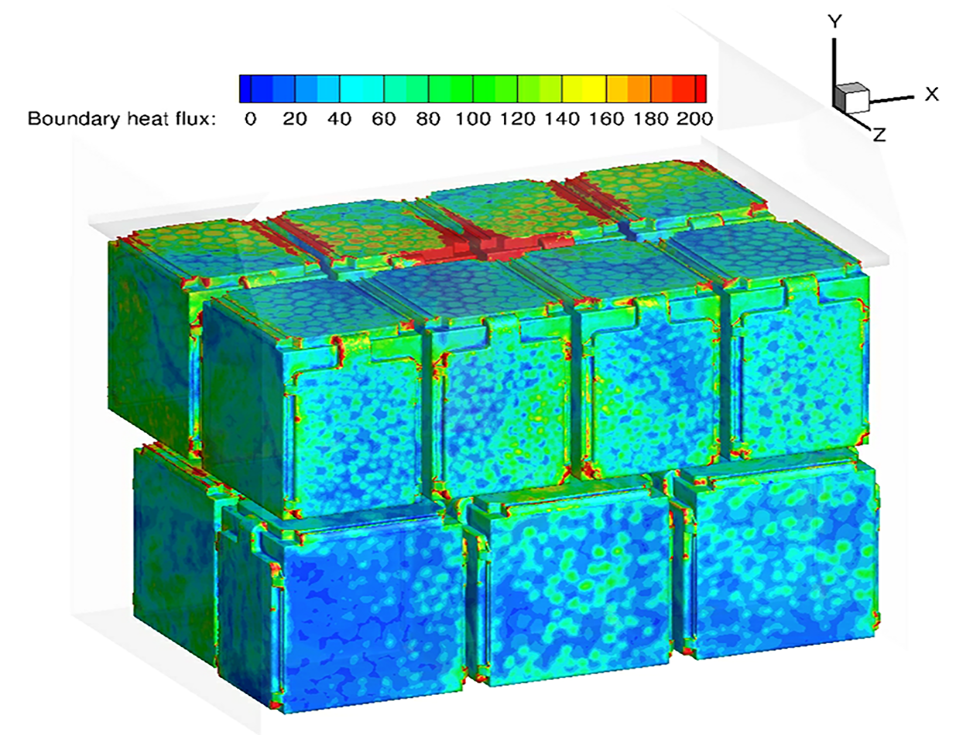

The vehicle's all-electric powertrain must be lightweight, powerful, and provide sufficient range. To satisfy these requirements, cutting-edge nickel-manganese- cobalt (NMC) lithium-ion batteries are used. The vehicle's 90 kWh battery pack provides 230 miles of range. Each wheel is powered independently using four 100 kW, 400 Nm electric motors along with a 7:1 gear reduction, resulting in over 10,000 Nm of wheel torque. Several novel technologies are employed in the electrified powertrain, including prototype thermal interface materials, distributed "supermodule" battery packs with independent contractors and unique heat exchanger designs.