Integrated Computational Materials Engineering (ICME)

Pure Nickel

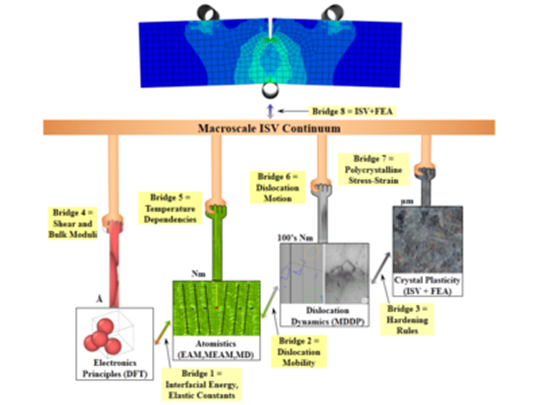

Pure nickel was chosen in a unique opportunity to employ the Integrated Computational Materials Engineering (ICME) methodology of multiscale modeling. Specifically, ICME was used to model an every day test that occurs in many testing facilities around the world, a three-point bend test. The metric for assessing a three-point bend test is the force-displacement curve garnered from the test. As a segway into the ICME methodology, the force-displacement curve, unlike a stress-strain curve, is not a direct result of macroscale simulations. Starting with the end goal in mind, a set of downscaling requirements is needed to fully ascertain a material behavior for pure nickel. Once the downscaling requirements have been determined relevant length scale studies can be decided upon. Each length scale study then has information that is upscaled to the next highest length scale (sometimes even providing information two or more length scales away) as well as providing information to the highest length scale where the downscaling requirements began. Figure 1 illustrates the flow of information that is required to meet the end goal of predicting how pure nickel would behave during a three-point bend test.

Schematic detailing the upscaling/downscaling relationships. Downscaling requirements are driven from the boundary value problem or highest length scale that needs to be solved. That information is then used from one length scale to the next to determine the upscaling requirements for solving the problem.