Integrated Computational Materials Engineering (ICME)

Inconel 600

Material Description

The Inconel 600 material is a nickel-chromium based alloy also known as alloy 600 or UNS N06600. It is an oxidation and corrosion resistant alloy used in extreme environments at high temperatures and pressures. The Inconel composition is given below:

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

|---|---|---|---|---|---|---|---|

| 72.0 min | 14.0 - 17.0 | 6.0 - 10 | 0.15 max | 1.00 max | 0.015 max | 0.50 max | 0.50 max |

Mechanical Properties

The mechanical properties of this alloy are given for tension and compression tests considering temperature and strain rate.

Tensile Properties

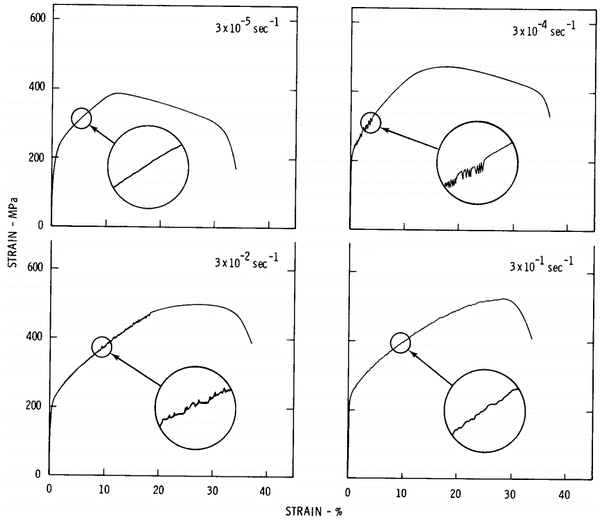

Strain rate sensitivity of Inconel 600 at 1200˚F[1].

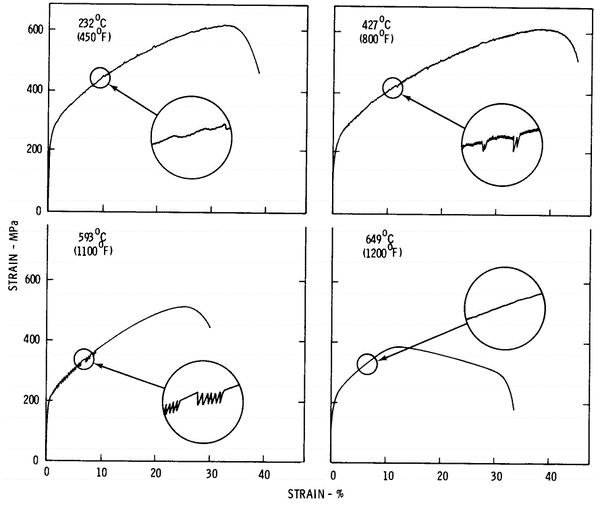

Temperature sensitivity of Inconel 600 at 3e-5 strain rate[2].

Compression Properties

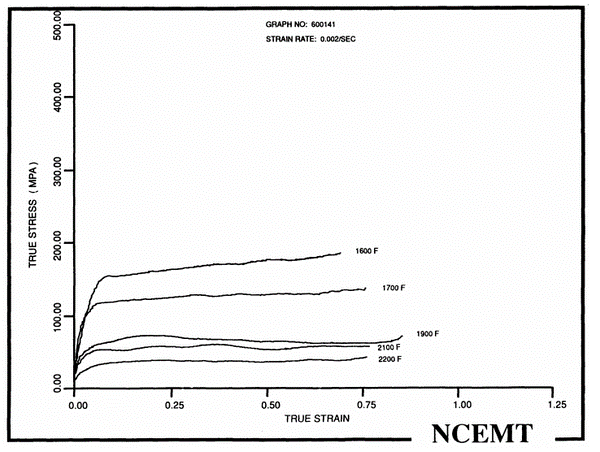

Temperature sensitivity of Inconel 600 during compression testing at 2e-3 strain rate[3].

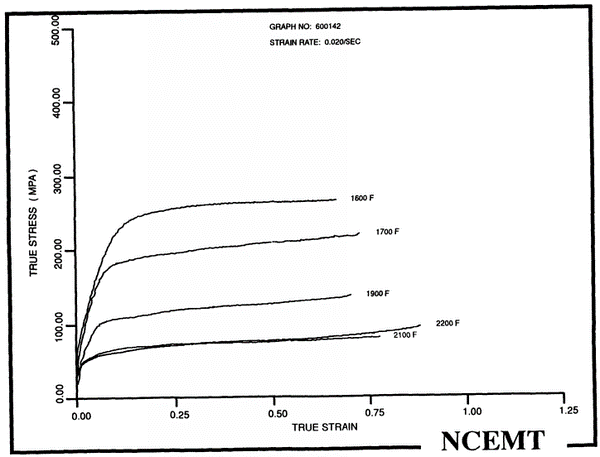

Temperature sensitivity of Inconel 600 during compression testing at 2e-2 strain rate[3].

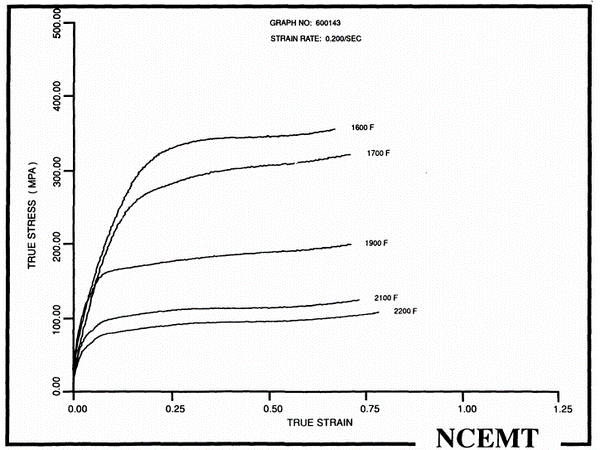

Temperature sensitivity of Inconel 600 during compression testing at 2e-1 strain rate[3].

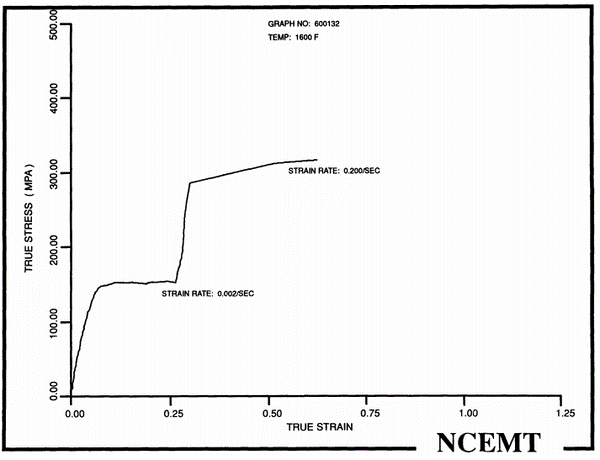

Strain rate sensitivity of Inconel 600 during compression testing at 1600˚F[3].

Fatigue Properties

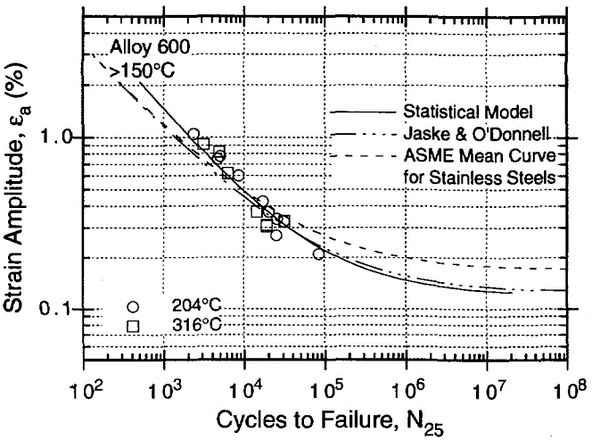

Fatigue life of Inconel 600 at T > 150˚C[4].

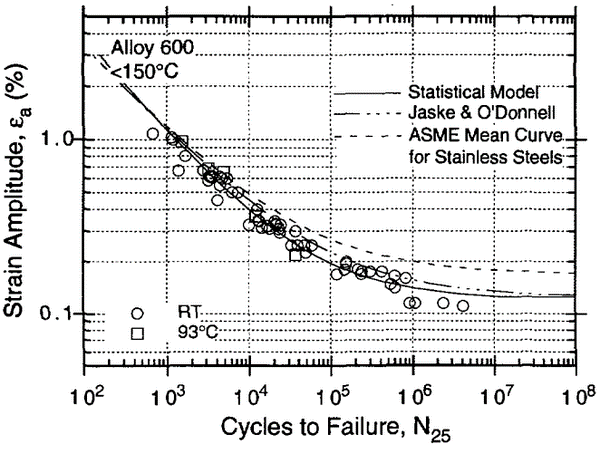

Fatigue life of Inconel 600 at T &60; 150˚C[4].

References

- ↑ M. R. Hill, “Mechanical Properties Test Data for Structural Materials Quarterly Progress Report for Period Ending October 31, 1976”, Oak Ridge National Laboratory, Dec. 1976. P 282.

- ↑ M. R. Hill, “Mechanical Properties Test Data for Structural Materials Quarterly Progress Report for Period Ending October 31, 1976”, Oak Ridge National Laboratory, Dec. 1976. P 277.

- ↑ H. A. Kuhn, “Atlas of Formability-Inconel 600”, National Center for Excellence in Metalworking Technology, Feb. 1991.

- ↑ J. Keisler. Et al., “Fatigue Strain-Life Behavior of Carbon and Low-Alloy Steels, Austenitic Stainless Steels, and Alloy 600 in LWR Environments”, Argonne National Laboratory, August 1995.