Integrated Computational Materials Engineering (ICME)

Civil Engineering Materials

Introduction

Civil engineering materials are key components to the design and maintenance of civil structures. Most of these structures are large in scale such as bridges, buildings, and dams.

Material Types

Materials that are widely used in the civil engineering practice include but are not limited to: reinforced concrete, asphalt, masonry, wood, structural steel, aluminum, and polymers.

Reinforced Concrete

Reinforced concrete is the most common civil engineering material. It is composed of concrete which is a combination of materials such as sand, fly ash, river rock, and cement.

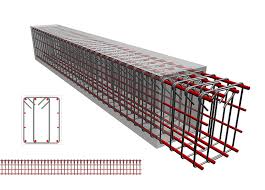

Figure 1: Internal view of reinforced concrete beam

Behavior

Concrete which is a combination of materials such as sand, fly ash, river rock, and cement, is extremely strong when subjected to compression but behaves in a brittle manner when exposed to tension. The "reinforced" component is provided by steel rebar (Fig. 1). This rebar provides the tensile capacity to reinforced concrete structures.

Benefits

The most desired quality of concrete is that it is readily available, and is usually composed of materials that can be found/produced locally. Concrete is also extremely durable under repeated loading conditions.

Drawbacks

Concrete is an extremely heavy material. At 150 pcf, large scale concrete structures can experience more loading from self-weight than from live loads.

Structural Steel

Structural steel is another civil engineering material that can be found in nearly all civil structures.

Figure 2: Steel piling used to shore a foundation slide

Behavior

Steel is common in the design of beams, frames, columns, and trusses. Steel

is strong in both tension and compression but is subject to many limit state

checks in design. Steel girders can span much longer distances than reinforced

concrete, but are more likely to buckle. A common application of structural

steel is foundation design. Steel piles (HP shapes) can be driven into

foundations (Fig. 2) to a minimum pile bearing capacity and then encased with

reinforced concrete. This adds a great deal of flexural and axial capacity as

well as protects the structural steel from corrosion.

Figure 2 is an example of steel pile foundation repair. Steel piling was driven

closely together to prevent the road from sliding further. This is a common

repair method for foundation slides.

Benefits

The flexibility of steel in structural design makes it an economic material. Many steel structures can be built up from smaller steel components. Common examples of this are frame design and plate girder design. Frames can be composed of multiple steel shapes (W-Shapes, Angles, HSS, etc.) that are rigidly connected by welds and bolts. Plate girders are common in long span bridge design. Plate girders are composed of large plates (5 feet or more in height) that are spliced together with full penetration welds and high strength bolts.

Figure 3: Structural steel plate girder buckling under combination of wind & construction loads

Drawbacks

Corrosion is the most common and most expensive problem with steel

structures. Protective coatings must be maintained throughout the life of the

structure or extreme section loss can occur. Steel is also susceptible to

buckling. High shear loads can buckle the webs of steel I-beams if stiffeners

are not designed. Steel beams are also subject to lateral torsional buckling

(shown in Fig. 3) and flexural buckling if adequate bracing is not incorporated

in design.

Figure 3 shows a set of plate girders after buckling laterally. The smaller

buckled members were temporary bracing components that buckled in compression.

Construction loads applied during lifting procedures and horizontal wind loads

are common causes of lateral torsional buckling of plate girders. The strength

of these flexural members is greatly reduced as a result of this buckling

failure.