Integrated Computational Materials Engineering (ICME)

MSF Calibration for cast C83600

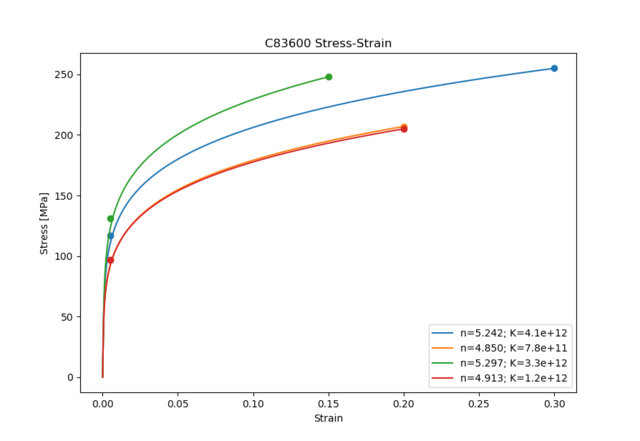

The original data for this calibration was in the form of stress-life data [1]. In an ideal case, a cyclic stress-strain curve can be used to convert the stress amplitude to a strain amplitude. In this case, neither a cyclic stress-strain curve nor a monotonic stress-strain curve was available for C83600. Instead, a Ramberg-Osgood fit of four different yield stresses, ultimate stresses, and elongations were generated, using the assumption that the ultimate stress occurred at the maximum elongation. Mechanical property data was used from [2]. The stress-life data was converted using the mean of these curves. The Ramberg-Osgood fits are shown with their fit parameters in Figure 1.

Figure 1. Ramberg-Osgood fit for C83600 using yield and ultimate stresses and elongations.

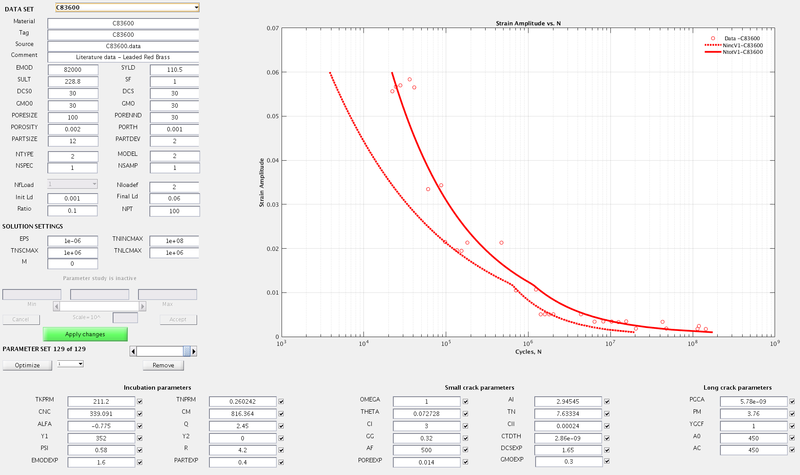

MSF Model Screenshot

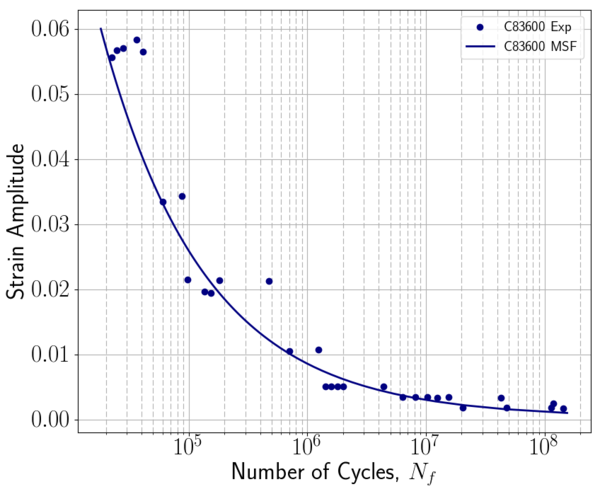

MSF Figure

References

1. Metals Handbook, 9th Edition, Volume 2, Properties and

Selection: Nonferrous Alloys and Pure Metals, American Society for Metals,

Metals Park OH, 1979, P 406

2. https://alloys.copper.org/alloy/C83600