Integrated Computational Materials Engineering (ICME)

Biological Sample Preparation for High Strain Rate Testing

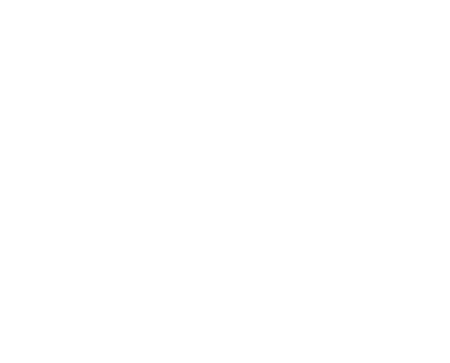

Porcine heads of healthy pigs were procured from a local abattoir in Maben, MS. These porcine heads (covered in plastic wrapping) were then stored in an iced container (~42 °F) and transported to Mississippi State University College of Veterinary Medicine, Starkville, MS. There, porcine brain samples were extracted and stored in containers filled with Phosphate Buffered Saline (PBS). PBS solution was chosen, because of its similar osmolarity and ion concentration as CSF (Prevostet al., 2011[1]). These containers were then stored in a cooler (~45 °F) and transported to the Center for Advanced Vehicular Systems (CAVS) for sample preparation. Standard bio-hazard safety protocols were followed. Using a cylindrical die of 30mm inner diameter, brain samples were extracted and cut to an average thickness of 15mm (Figure 1).

Figure 1. Sample extraction from fresh (< 3 hour post-mortem) from (a) porcine brain, and (b) sample extraction using a 30 mm inner diameter die in the superior-inferior direction, and (c) the sample prepared for testing.

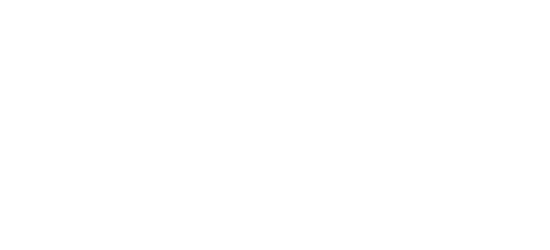

This gave an aspect ratio of 0.5, which was based on the work conducted by Gray and Blumenthal (2000)[2]. Brain extractions and dissection required approximately 1 hour for completion, and all compression experiments were conducted within 3 hour post-mortem. In all, 20 porcine brains were used for testing, with 35 extracted viable samples that were tested. Due to the loss of samples in the experiments (sample problems, incision errors, variation in cross-section thickness and unsuccessful testing), results of 26 samples (that came from 15 porcine brains) were successfully obtained and used for the following analyses. Details of the samples obtained and porcine brains used along with testing conditions are given in Table 1. No preconditioning was performed for our testing as specified by Fung (1993)[3] as quasi-static preconditioning has no meaning for high strain rate testing as conducted in this study.

Table 1. Details of samples, animal numbers and testing conditions are each strain rate.

Reference

1. Prevost, T., P., Balakrishnan, A., Suresh, S., Socrate, S., (2010)

“Biomechnics of brain tissue.” Acta BioMat 71 pp. 83-95.

2. Gray, G., T., Blumenthal, W., R., (2000) “Split-Hopkinson Pressure Bar for

Soft Materials” ASM Handbook, Mechanical Testing and Evaluation, ASM

International, Materials Park, OH, 8 pp. 488-496.

3. Fung, Y., (1993) “Biomechanics: Mechanical Properties of Living Tissues”,

2nd Edition Springer, USA, pp. 242-311.