Integrated Computational Materials Engineering (ICME)

AA7050-T7451 тАУ MultiStage Fatigue

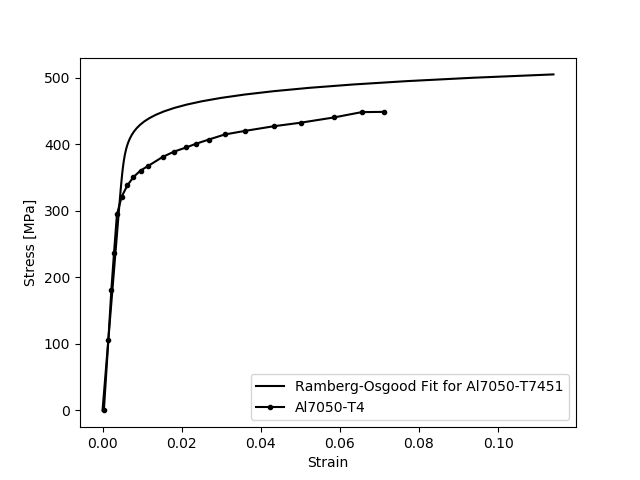

The original data for this calibration was in the form of stress-life data. In an ideal case, a cyclic stress-strain curve can be used to convert the stress amplitude to a strain amplitude. In this case, neither a cyclic stress-strain curve nor a monotonic stress-strain curve was available for the specific temper of Al 7050. Instead, a Ramberg-Osgood fit of the yield stress, ultimate stress, and elongation was generated, using the assumption that the ultimate stress occurred at the maximum elongation. There is naturally uncertainty related to all of these assumptions, but the generated Ramberg-Osgood stress-strain curve had similar characteristics as other Al 7050 stress-strain curves, lending credibility to the assumptions. The Ramberg-Osgood fit is shown in Figure 1.

Figure 1. Ramberg-Osgood fit for a Al 7050-T7451 alloy compared to experimental data for Al 7050-T4 to show the similar shapes.

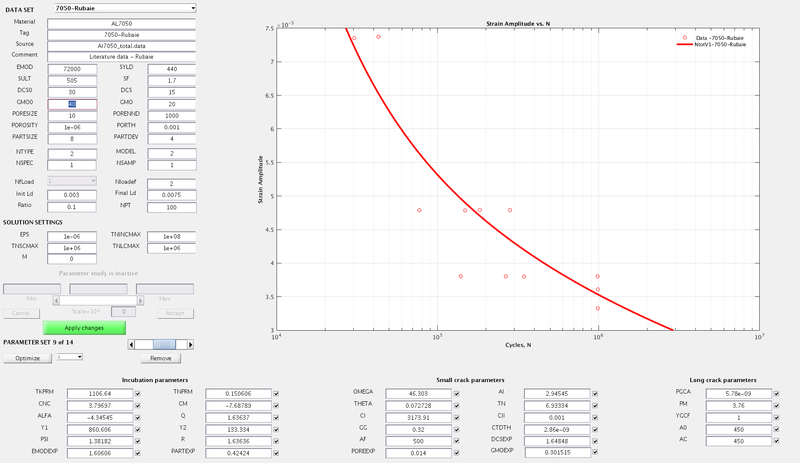

MSF Model Screenshot

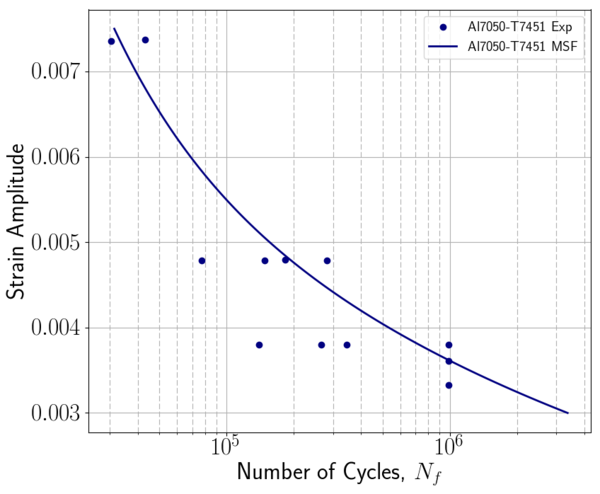

MSF Figure

References

Al-Rubaie, Kassim S., et al. "Effect of pre-strain on the fatigue life of 7050-T7451 aluminium alloy." Materials Science and Engineering: A 464.1-2 (2007): 141-150.