InSitu-AM

Existing data acquisition systems for additive manufacturing are typically proprietary, process specific, and limited to post-process data analysis. They often rely on isolated tools tied to specific hardware or sensors, which prevents synchronized, real-time insights and integration across platforms. InSitu-AM addresses these limitations by introducing a modular, Robot Operating System 2 (ROS 2) based communication and data infrastructure. Every connected device publishes standardized data streams within a shared communication architecture. These streams are time synchronized, interoperable, and recorded into a unified database schema, enabling correlation between machine states, sensor data, and process parameters in real time.

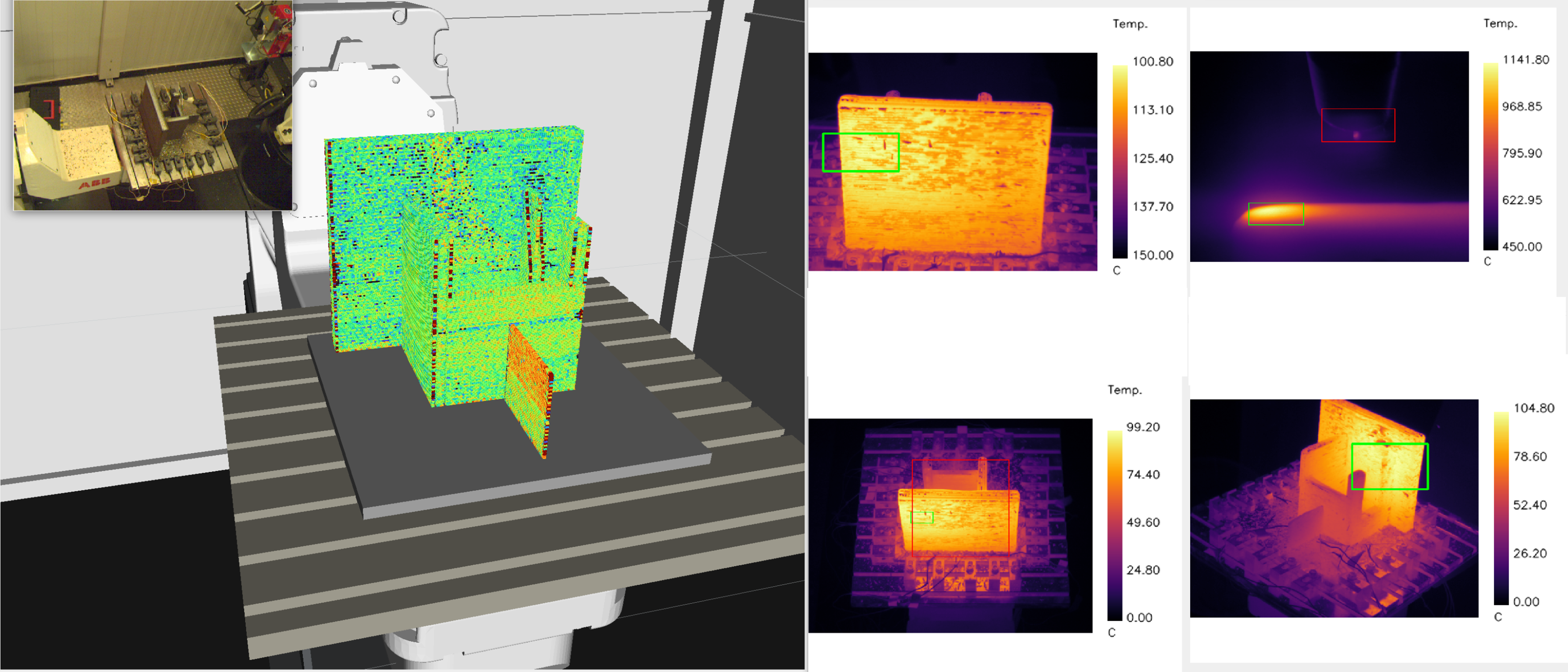

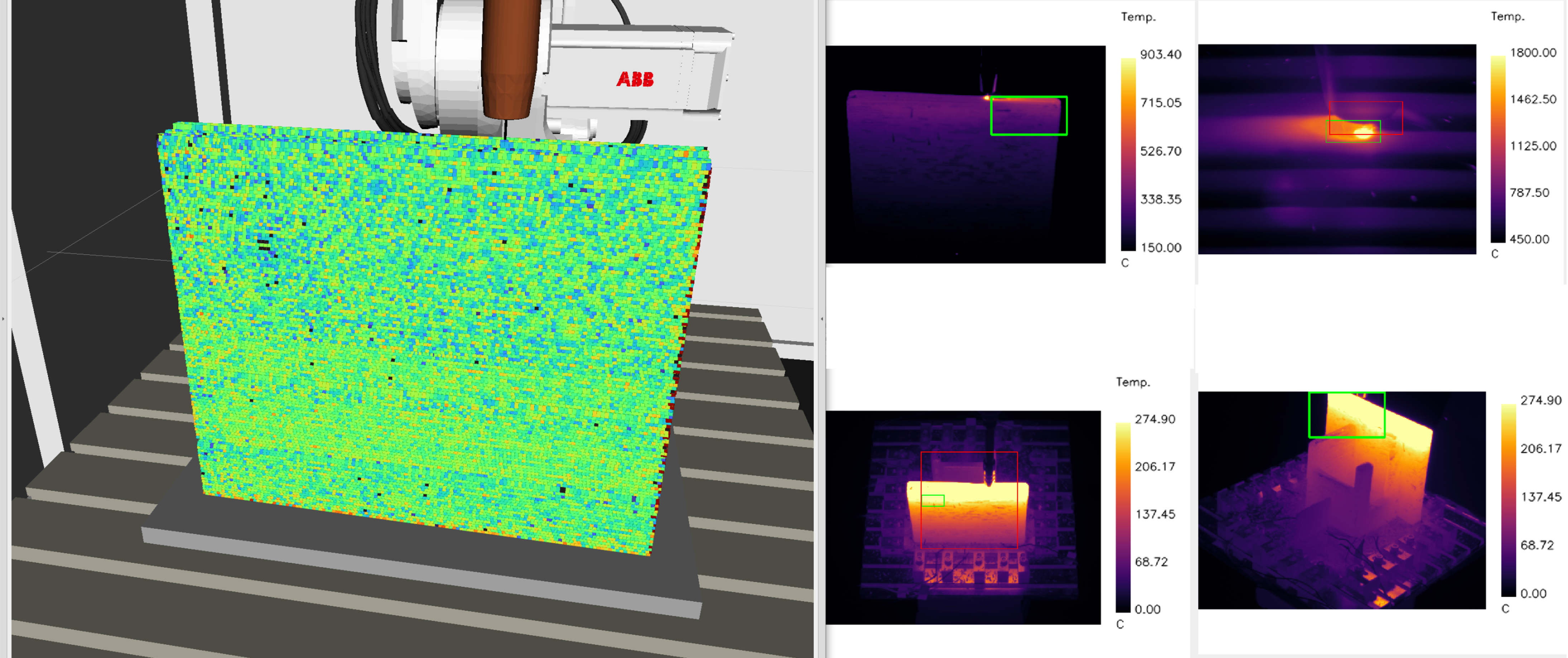

Example of projecting point cloud data from a stereo depth camera within the virtual environment.

Infrared data taken from a fixed location during a single layer of a build.

Voltage point cloud data over a single layer of a build in the virtual environment.

What does InSitu-AM Software Provide?

- Multi-modal data fusion through a common message interface, allowing heterogeneous devices to communicate without vendor specific middleware.

- Real-time analysis and feedback control, enabling process adjustments based on sensor conditions.

- Scalable architecture, where additional sensors and subsystems can be integrated or substituted without redesigning the software stack.

- Extensible ROS-based libraries and visualization tools for data processing, and long-term development of digital twins for AM.

- Bridging the gap between machine control and data collection for process qualification, InSitu-AM transforms additive manufacturing from a collection of isolated systems into a connected, interoperable, data-driven ecosystem.

InSitu-AM runs above the AM process, powered by ROS 2 allowing for flexible, data-driven solutions for AM data collection, real-time analysis, and feedback controls. This not only improves how data is collected and shared, but enables advanced analysis, modeling, and true digital twin development over time. InSitu-AM is currently deployed on wire-arc directed energy deposition processes utilizing ABB robots and Fronius weld sources. Development is ongoing to further the capabilities (for this process and hardware) and extend to additional AM processes, sensors/hardware, and motion systems.

Example of high order data streams in between layers. From left to right - Optical camera, Welding voltage point cloud, and infrared images.

Same as above, but during deposition, and without the optical camera feed.